BRANSON Ultrasonic welding

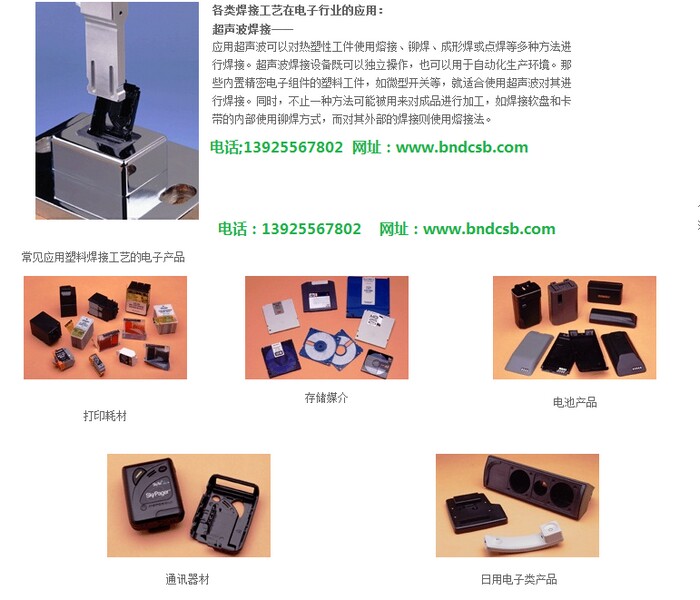

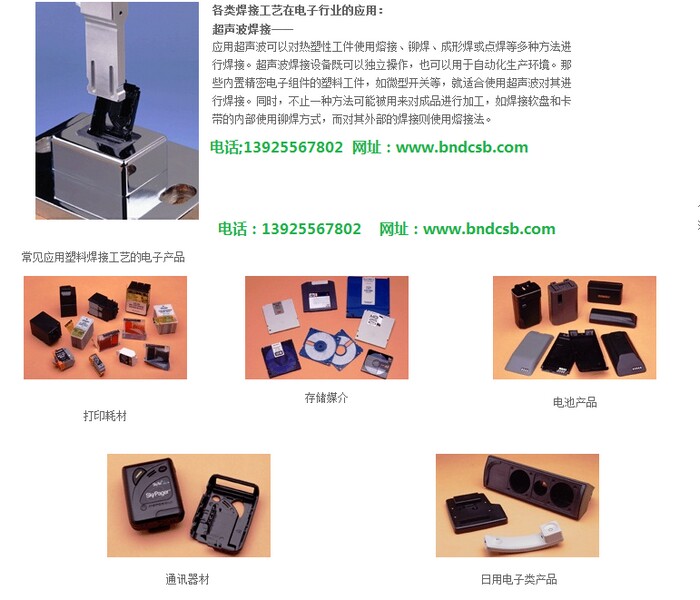

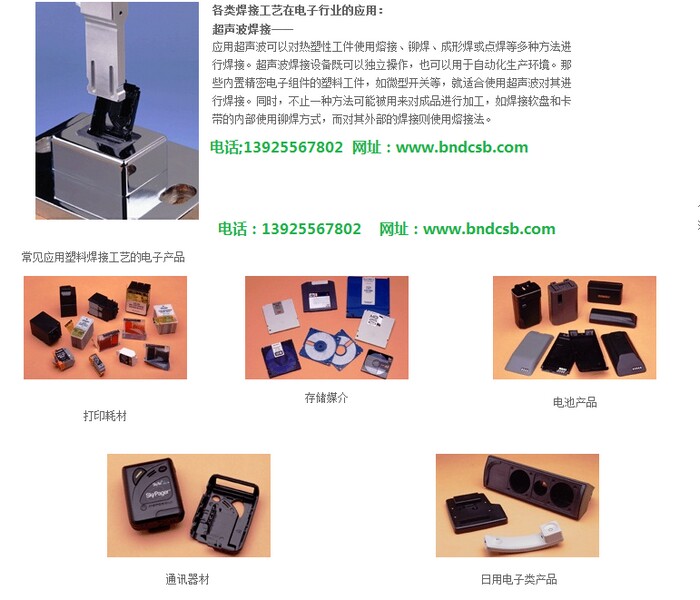

Application of various welding processes in the electronics industry:

Ultrasonic welding

The thermoplastic workpiece can be welded by welding, riveting, forming or spot welding with ultrasonic wave. Ultrasonic welding equipment can be operated independently or used in automated production environments. Plastic parts with built-in precision electronic components, such as micro switches, are suitable for ultrasonic welding. At the same time, more than one method may be used to process the finished product, such as riveting the inside of the welded floppy disk and cassette tape, and welding the outside of it using the weld method.

Vibration friction welding

Vibration friction technology is the most ideal method for welding irregular shaped plastic parts and semi-crystalline resins. The use of vibration friction welding equipment can seal the workpiece and is ideal for welding products filled with liquid or powder, such as ink cartridges.