BRANSON Ultrasonic rubber cutting

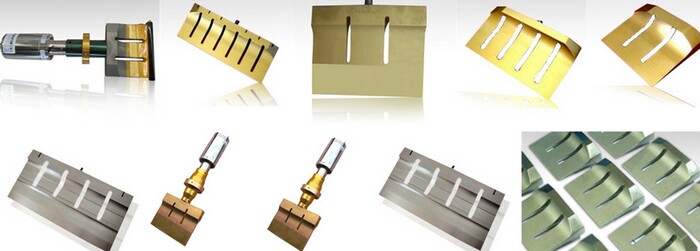

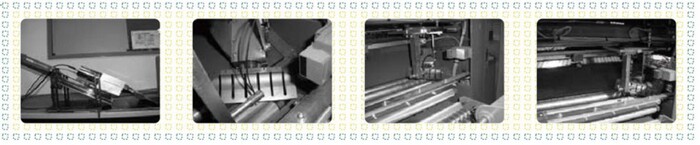

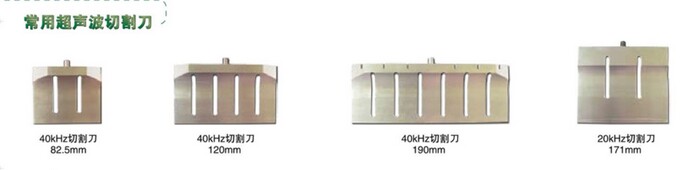

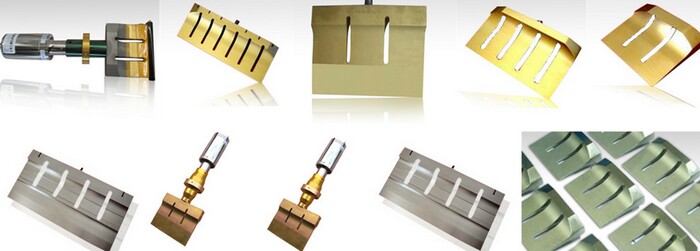

The principle of ultrasonic cutting is to convert 50/60Hz current into 20, 30 or 40kHz electrical energy through an ultrasonic generator. The converted high frequency electrical energy is again converted by the transducer into a mechanical vibration of the same frequency, which is then transmitted to the cutting knife by a modulator device that can change the amplitude. The cutter transmits the received vibration energy to the cutting surface of the workpiece to be cut, where the vibration energy is used to cut the rubber by activating the rubber molecular energy and opening the molecular chain. The main components of an ultrasonic cutting system include ultrasonic generator, transducer/modulator/cutter triad and various cables.

Advantages of ultrasonic tire rubber cuttingThe above are the need for experienced equipment, mold engineers to analyze and evaluate the feasible plan. The technology and experience of engineers are related to the quality and cost of product welding. The technology and experience of engineers in each company are different, so it is necessary to understand the technical level of engineers from the successful cases of previous products. Careful consideration is needed before purchasing equipment and making molds. It is related to the cost and time of operation of your entire product.